Refractometers are used extensively within the world’s food and beverage industries whether it’s for precise measurement of concentration at the start of manufacture, or for quality control at the end of a process.

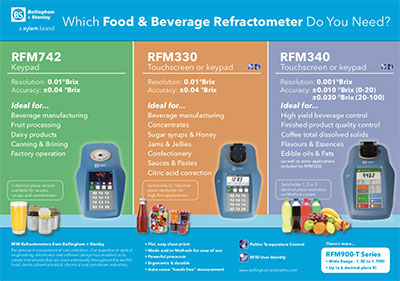

Our “Which refractometer do you need?” infographic guides you through the benefits of RFM digital refractometers for food & beverage applications. It offers a quick and simple way of determining which Bellingham + Stanley refractometer best suits your business needs.

Common instrumentation throughout the Food and Beverage industry

One of the most commonly used instruments throughout the fruit and veg industry is a refractometer for determining the Brix content of sugary foods. A refractometer for monitoring fruit ripening on trees is of utmost importance as farmers are judged on the sugar content at the point of sale for supermarkets and cooperatives.

One of the most commonly used instruments throughout the fruit and veg industry is a refractometer for determining the Brix content of sugary foods. A refractometer for monitoring fruit ripening on trees is of utmost importance as farmers are judged on the sugar content at the point of sale for supermarkets and cooperatives.

It’s worth knowing that when these RFM refractometers are equipped with flow cells (available separately), the refractometer can link to a separate saccharimeter and form a high-precision sugar purification system that can be used to process and pay for sugar beet and cane. It really is one of the most cost-effective purity systems available.

Together fizzy soft drinks and mixed juice drinks make up one of the largest areas of the food and beverage industry. These drinks are made from a blend of expensive flavours, natural and synthetic sweeteners and unique ingredients like caffeine and preservatives. Refractometers form part of a comprehensive food safety and quality control, as well as aiding in the ability to maintain production yield, thus keeping costs and profits in check.

- Refractometers such as the RFM330-M are ideal for syrup mixing and dilution control.

- Durable refractometers designed for the factory environment, such as the RFM700-M Series are commonly used within the manufacturing of a variety of soups, sauces and food pastes for blending control.

- High-precision Peltier temperature-controlled refractometers operating at elevated temperatures are used to determine mixing ratios of oils, such as corn or sunflower oil, for food use.

- Refractometers with a wide measuring range are used by companies looking for accurate and reproducible quality control for determining the taste in food and beverage products.

In beer and wine, refractometers are used by farmers who have a need to continuously monitor the sugar content of fruit cultivation so that they can harvest at the perfect time for delivery og the grapes to the cooperatives. These in turn pay against sugar (fructose) content, quantity (weight) and quality (micro). There are a number of different scales used across the globe for measuring grape must including (% mass, Brix, Oechsle, Baume, probable alcohol).

In beer and wine, refractometers are used by farmers who have a need to continuously monitor the sugar content of fruit cultivation so that they can harvest at the perfect time for delivery og the grapes to the cooperatives. These in turn pay against sugar (fructose) content, quantity (weight) and quality (micro). There are a number of different scales used across the globe for measuring grape must including (% mass, Brix, Oechsle, Baume, probable alcohol).

You can download our infographic here or visit our contact page to get in touch with a member of our Customer Care team, who’ll be happy to advise on which food and beverage refractometer is best for you.

To learn more about Bellingham + Stanley and its 100 years of refractometer expertise click here.

To discover the complete range of digital refractometers made in the UK then please take a look at our refractometer overview page. For more information about Monitoring and Quality Control for the Food & Beverage Industry then please visit the application page at Xylem Analytics.