Calculating the Carbon-Type Composition of Insulating Oils of Petroleum Origin in accordance with ASTM D 2140

Using the RFM900-T Peltier temperature controlled refractometer “ASTM D 2140” Method

The measurement of refractive index is commonplace within petrochemical and associated industries and its determination is cited in many technical documents and standard test methods such as ASTM D 2140 that describes “Standard Practice for Calculating Carbon-Type Composition of Insulating Oils of Petroleum Origin.”

However, refractive index measurement forms only part of the overall experiment and once other parameters have been established, the resultant carbon-type compositions of the electrical insulating oil under test have to be established using a multidimensional graph that is at best, difficult to interpret. Refractometer manufacturer Bellingham + Stanley has established a Method within their latest RFM900-T Series instruments that (once all parameters are known) automatically calculates and displays the relevant information on the instrument display and/or printed report. This eliminates the frustration of manual interpretation and provides far more reliable results, especially if different operators are involved in the process.

Background

ASTM D 2140 is a rapid test method for determining the carbon-type composition of electrical insulating oils of the types commonly used in electric power transformers and transmission cables. It is primarily intended for use with new oils, either inhibited or uninhibited.

ASTM D 2140 may be used to determine the carbon-type composition of mineral insulating oils by correlation with basic physical properties. For routine analytical purposes it eliminates the necessity for complex fractional separation and purification procedures. The test method is applicable to oils having average molecular weights from 200 to above 600, and 0 to 50 aromatic carbon atoms.

Carbon-type composition is expressed as percentage of aromatic carbons, percentage of naphthenic carbons, and percentage of paraffinic carbons. These values can be obtained from a correlation chart (available from ASTM) if both the viscosity-gravity constant (VGC) and refractivity intercept (ri) of the oil are known. Viscosity, density and relative density (specific gravity), and refractive index are the only experimental data required for use of this test method.

RFM900-T Software

ASTM D 2140 requires measurement of it’s viscosity, density, relative density (specific gravity) and refractive index in order to calculate the viscosity-gravity constant (VGC) and refractivity intercept (ri) prior to using a three dimensional correlation graph to determine carbon-type composition of insulating oils.

The use of a correlation graph is likely to lead to some variation, caused by operator error visually interpreting the results.

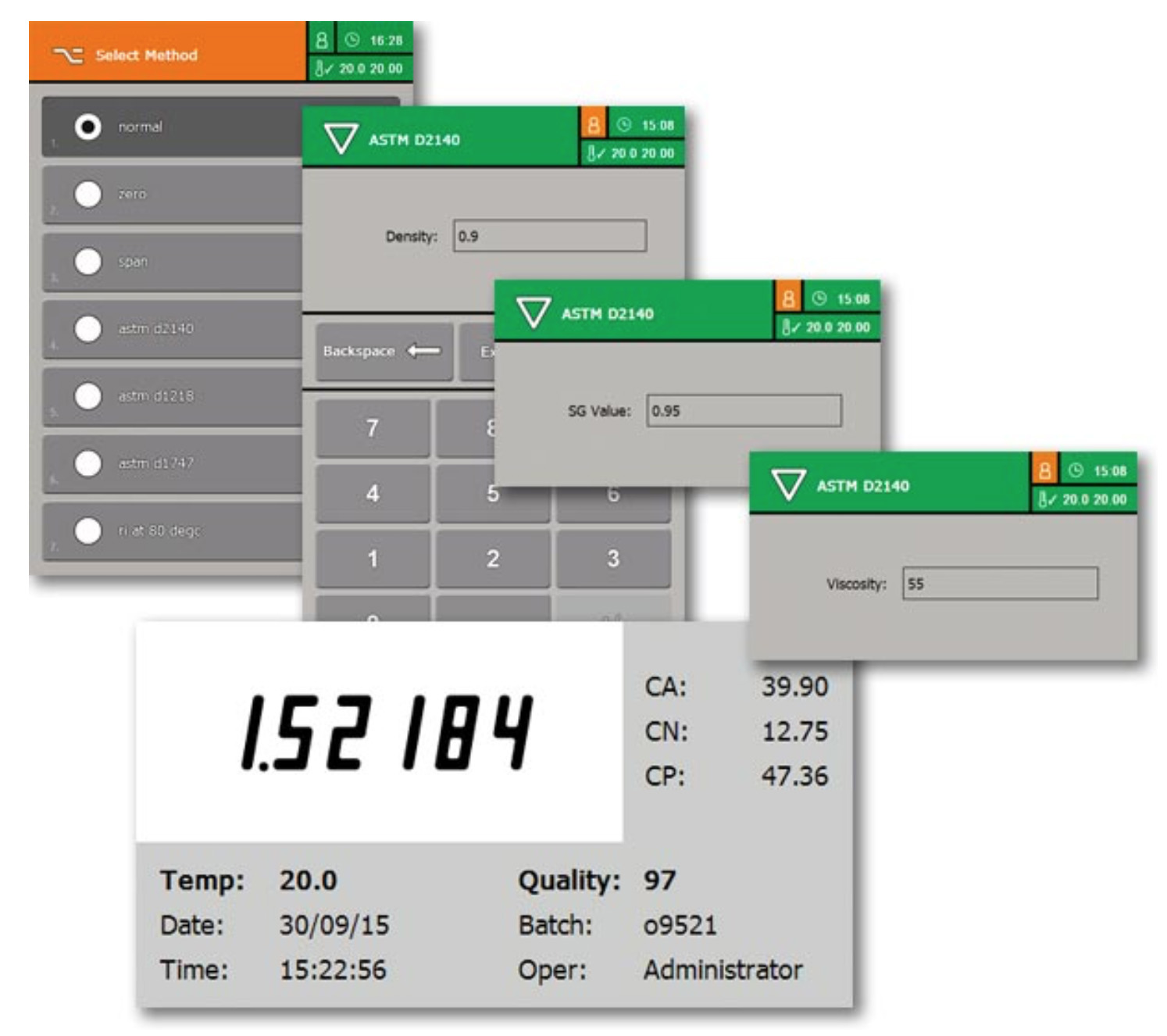

Software installed in RFM900-T Series refractometers allows input of viscosity, density and relative density (SG) at the specified measurement temperatures, and then instantly performs the calculations, providing a report of results without the need for visual interpretation.

(fig.2 ASTM D 2140 Method selection, experimental data entry and on-screen result)

Advantages

1. Use of a digital refractometer will give better repeatability in obtaining refractive index values compared to visual Abbe refractometers.

2. Use of software within the RFM900-T Series refractometer offers increased precision in relation to interpretation of results when compared to the visual use of the correlation table. This is particularly true where a number of different operators are performing the analysis.

Use of the RFM900-T software to determine results in accordance with ASTM D 2140

The RFM900 incorporates a Method that enables automatic calculation of:

- Aromatic Carbons

- Naphthenic Carbons

- Paraffinic Chain Carbons

The Method is loaded from the scale library within the instrument and is then selected using the Method button. The sample is applied to the prism and the experiment is initialized on the placement of the sample cover.

Results

The results are displayed when the measurement has been completed. The RI of the sample will be displayed in large characters, and the special ASTM D 2140 values appear next to the RI measurement (Figure 2).

RFM900-T Series refractometers:

Features & benefits for the petrochemical industry

- Wide measuring range covering 1.30 to 1.70 RI with 6 decimal place precision

- Peltier temperature control up to 80 °C with precision stability to ±0.02 °C eliminating the need for a waterbath

- Kalrez® prism gasket materials protect instrument against aggressive samples

- Measurement Quality indicator shows reading reliability

- ASTM D 2140 method for automatic calculation of Carbon-type composition

- Petrochemical Methods include:

- ASTM D 1218 test method for Refractive Index measurement of hydrocarbons at 589nm (Annex 2 - sodium).

- ASTM D 5006 – aviation fuel system icing inhibitors ASTM D 1218 – RI determination of hydrocarbons

- (Annex 2 at 589nm)

- ISO 22241-2 for DEF/AdBlue® manufacture & fleet management (handhelds & special models)

Footnotes & Acknowledgements: Users of the method should consult with ASTM and obtain an original copy of the method in order to ascertain suitability.

This document is intended as an introduction to the software of the RFM900-T Series refractometers and provides a brief summary of the test method. It is not designed to be a replacement or actual test method.

Bellingham + Stanley recommends that users adopting the RFM900-T ASTM D 2140 Method to determine Carbon-Type composition continue to carry out infrequent checks by way of original method to prove results as part of GLP.

Although Bellingham + Stanley has done everything possible to ensure that results obtained match those from the published method, no responsibility is taken for the calculated results or indeed the source data taken from the method itself.

AdBlue® is a registered trademark of the VDA Verband der Automobilindustrie e.V.

Kalrez® is a registered trademark of DuPont Performance Elastomers LLC.

All copyright acknowledged.

© 2019 Xylem, Inc. All rights reserved. Bellingham + Stanley is a trademark of Xylem Inc. or one of its subsidiaries.